At Essiz Metal, we place great value on modern technologies that enable us to machine metal with the highest precision and efficiency. One of the cornerstones of our production process is CNC milling. With this technology, we combine computer-controlled accuracy with the experience of our skilled team. The result: high-quality products that meet the strictest requirements across various sectors.

What is CNC milling?

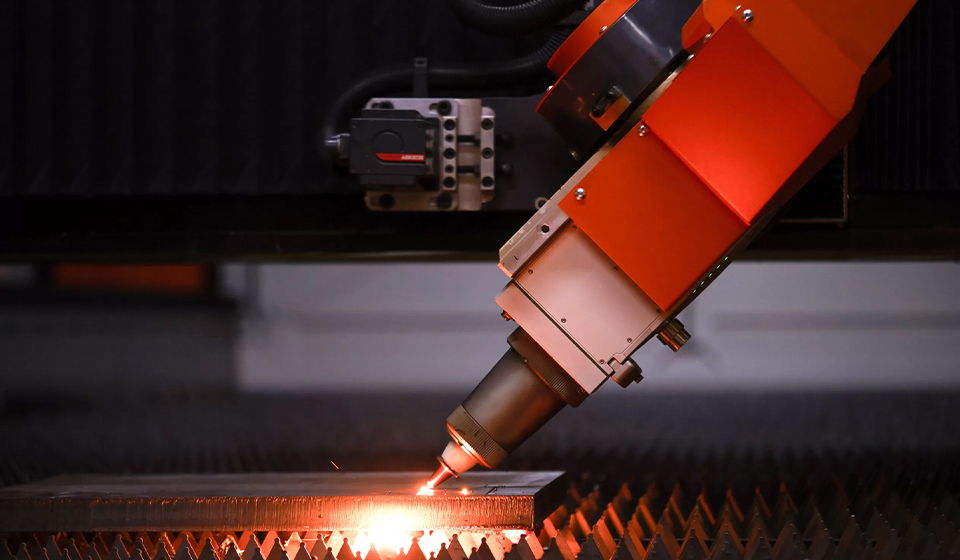

CNC milling is a machining process in which material is removed using rotating cutting tools. The entire process is controlled by a computer (CNC = Computer Numerical Control), allowing highly complex shapes, patterns, and details to be produced with exceptional accuracy.

This technology makes it possible to manufacture both small components and large structures. Whether it concerns prototypes or series production, CNC milling provides the flexibility and reliability that modern industries require.

The advantages of CNC milling at Essiz Metal

We distinguish ourselves through a combination of advanced machinery and years of experience. Thanks to our machine park and skilled workforce, we can offer the following benefits:

High precision: Accuracy up to one-hundredth of a millimeter.

Flexibility: Suitable for a wide range of materials such as steel, stainless steel, aluminum, and copper.

Complex shapes: Ability to produce intricate geometries that are not possible with conventional methods.

Efficiency: Short production times without compromising quality.

Consistency: Every part meets the same quality standards, regardless of batch size.

Applications of CNC milling

CNC milling is highly versatile and applied in various sectors:

Machine building: Production of high-precision machine parts.

Automotive: Manufacturing of components that require safety and durability.

Shipbuilding: Parts that can withstand heavy conditions.

Construction and architecture: Complex metal forms for building projects.

Industrial installations: Components that require reliability and long service life.

Thanks to the versatility of CNC milling, we can offer both standard products and customized solutions, fully tailored to the wishes of our customers.

Quality and craftsmanship

At Essiz Metal, quality always comes first. Our CNC milling machines are operated by experienced specialists who are continuously trained in the latest techniques. In addition, we conduct strict quality checks during and after the production process. This ensures that every product leaving our factory meets the highest standards.

Innovation for the future

We believe that investing in innovative technology and sustainable production processes is the key to success. CNC milling enables us to meet not only current but also future challenges in metalworking. By continuously modernizing and integrating new methods, we continue to provide our customers with the most reliable and efficient solutions.

Why choose Essiz Metal?

Because we offer more than just a machining process. We are a partner who thinks along, advises, and delivers customized solutions. With our expertise in CNC milling, we ensure that your projects are carried out with the highest precision and within the desired timeframe.

Hic kayit yok!

Essiz Metal was founded in 2008 and, in line with customer demands and technological developments, has grown into its current position. The main activity of our company is sheet metal cutting and bending. We operate cutting and bending machines with a capacity of 15 mm and a length of 6000 mm, as well as CNC laser cutting machines of 12000 x 3000 mm capable of processing sheets up to 50 mm.

COMPANY PROFILEYears of Experience

m2 Production Area

Tons Annual Production