At Essiz Metal, we understand that welding is one of the most important processes in metalworking. Without high-quality welding techniques, durable structures and reliable products cannot be achieved. That is why we invest in the most advanced welding methods: TIG, MIG, and MAG welding. With our experienced team and modern equipment, we deliver welding work of the highest quality, meeting both national and international standards.

What is TIG welding?

TIG (Tungsten Inert Gas) welding is a process in which a tungsten electrode is used, and an inert gas (such as argon) protects the weld pool from oxidation. This process is known for its extremely high precision and is often used for thin materials or where a visually perfect weld is required. With TIG welding, we can join stainless steel, aluminum, and other non-ferrous metals seamlessly and cleanly, resulting in a strong, smooth weld without spatter or contamination.

What is MIG/MAG welding?

MIG (Metal Inert Gas) and MAG (Metal Active Gas) welding are arc welding processes that use a continuous wire feed. The difference lies in the shielding gas: MIG uses an inert gas (such as argon or helium), while MAG uses an active gas (such as carbon dioxide or a mixture of argon and CO₂). These techniques are highly efficient for large series and thick materials. The process is relatively fast, cost-effective, and produces a strong bond.

Our expertise in welding technology

At Essiz Metal, we combine many years of experience with modern technology. Whether it concerns one-off projects, small series, or large-scale production, we have the knowledge and capacity to successfully complete every welding task. Our team consists of certified welders who are continuously trained according to the latest standards and safety regulations.

Our key advantages:

High quality and precision in all welding processes

Experienced and certified welders

Suitable for various materials: steel, stainless steel, aluminum, and more

Efficient production, even in large volumes

Durable and reliable connections

Applications of TIG, MIG, and MAG welding

The welding techniques we apply are used across various sectors, including construction, machine building, automotive, shipbuilding, and industrial installations. Thanks to the versatility of these processes, we can weld both small parts and large structures safely and sustainably.

Quality and safety first

At Essiz Metal, quality is always central. We conduct strict quality checks during and after the welding process. Furthermore, we work fully in accordance with applicable European standards and safety guidelines. This ensures that our customers always receive a reliable and durable product.

Why choose Essiz Metal?

Because we believe that welding is more than just joining metals. It is a craft that requires precision, knowledge, and dedication. With our expertise in TIG, MIG, and MAG welding, we offer not only a technical solution but also a reliable partner who thinks along with your project. Whether it is a complex industrial structure or a custom solution, with us you are assured of the best results.

Hic kayit yok!

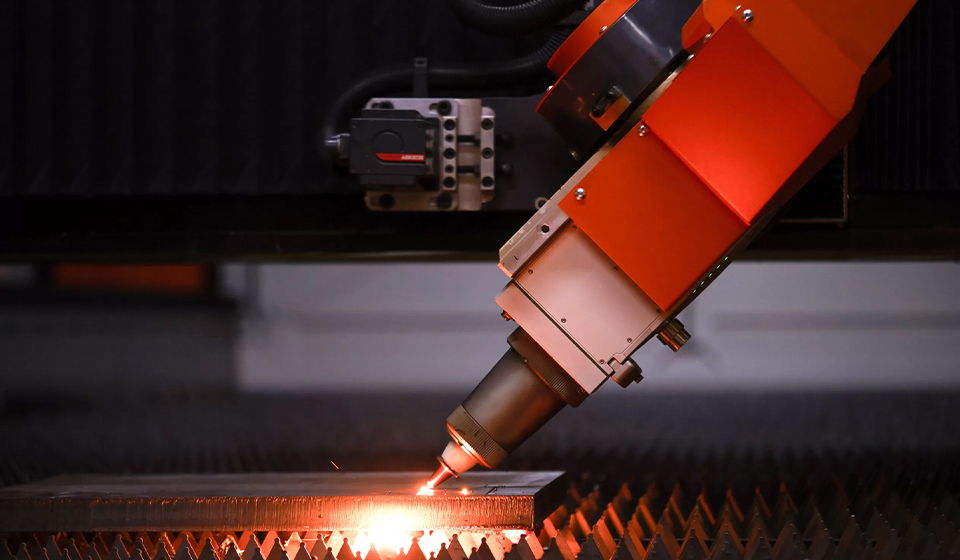

Essiz Metal was founded in 2008 and, in line with customer demands and technological developments, has grown into its current position. The main activity of our company is sheet metal cutting and bending. We operate cutting and bending machines with a capacity of 15 mm and a length of 6000 mm, as well as CNC laser cutting machines of 12000 x 3000 mm capable of processing sheets up to 50 mm.

COMPANY PROFILEYears of Experience

m2 Production Area

Tons Annual Production