At Essiz Metal, we believe that a product is only truly complete when it is not only manufactured with precision but also assembled with craftsmanship. Assembly forms the final, yet highly important, stage in our production process. Thanks to our experience, modern facilities, and dedicated staff, we are able to provide high-quality assembly solutions that perfectly match the needs of our customers.

What is assembly?

Assembly is the process of bringing together individual components into a complete product or structure. This can range from simple assemblies of a few parts to complex systems with hundreds of components. For us, assembly means more than just putting materials together; it is a combination of precision, craftsmanship, and quality control.

Our approach

At Essiz Metal, we follow a structured and customer-oriented approach. Every assembly project begins with thorough preparation, where technical drawings and specifications are carefully analyzed. Our experienced assembly team then ensures efficient execution, supported by modern tools and equipment.

Our working method is characterized by:

Precision: every detail is carefully checked.

Efficiency: short lead times without compromising quality.

Flexibility: suitable for both small series and large-scale production.

Quality assurance: continuous checks throughout the entire process.

The advantages of assembly at Essiz Metal

Our assembly solutions offer many benefits to our customers:

Full-service: from individual components to fully finished products.

Time and cost savings: no need for additional processing or outsourcing.

Durability: we use high-quality materials and reliable fastening methods.

Versatility: we provide assembly services for various sectors, including construction, automotive, machinery, and industry.

Applications of assembly

Our assembly activities are applied in different industries:

Metal constructions: assembling frames, beams, and supporting structures.

Machine building: assembling components into complete machines.

Automotive: assembly of metal components for vehicles.

Industrial installations: assembly of complex systems ready for immediate use.

Thanks to our broad experience, we can deliver both standard solutions and tailor-made services.

Quality and safety

At Essiz Metal, safety always comes first. Our technicians work in accordance with the strictest European standards and guidelines. In addition, we carry out extensive quality checks to ensure that every product leaving our workshop fully meets the required specifications.

Innovation and future-oriented work

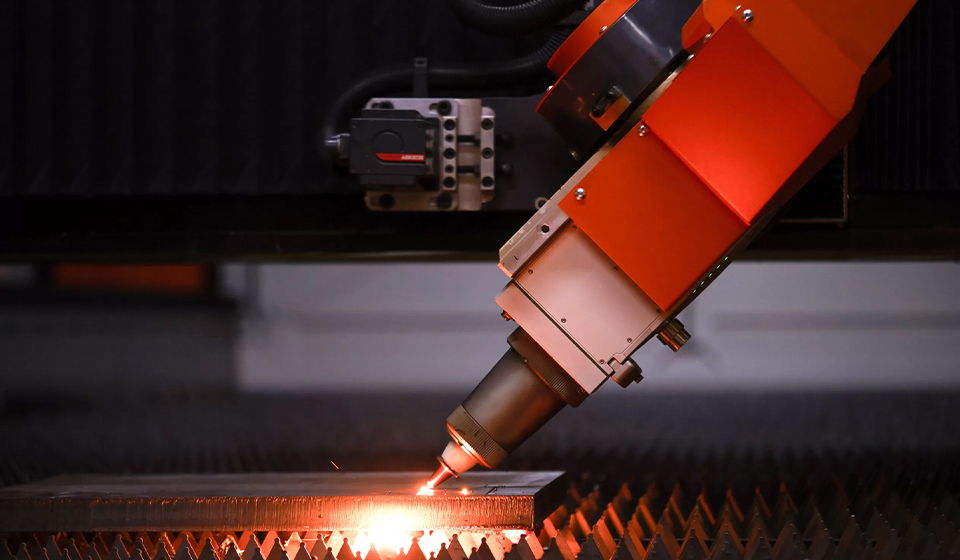

We continuously invest in modern assembly equipment and new techniques. This allows us to provide our customers with innovative solutions that meet the demands of the future. Whether it is automation, robot-assisted assembly, or sustainable fastening methods, we always stay one step ahead.

Why choose Essiz Metal?

Because we are more than just a manufacturer. We are a reliable partner who manages the entire process from production to assembly. Our expertise, modern facilities, and customer-oriented approach ensure that your projects are always delivered on time and to the highest standards.

At Essiz Metal, we turn individual parts into a whole – with craftsmanship, precision, and dedication.

Hic kayit yok!

Essiz Metal was founded in 2008 and, in line with customer demands and technological developments, has grown into its current position. The main activity of our company is sheet metal cutting and bending. We operate cutting and bending machines with a capacity of 15 mm and a length of 6000 mm, as well as CNC laser cutting machines of 12000 x 3000 mm capable of processing sheets up to 50 mm.

COMPANY PROFILEYears of Experience

m2 Production Area

Tons Annual Production