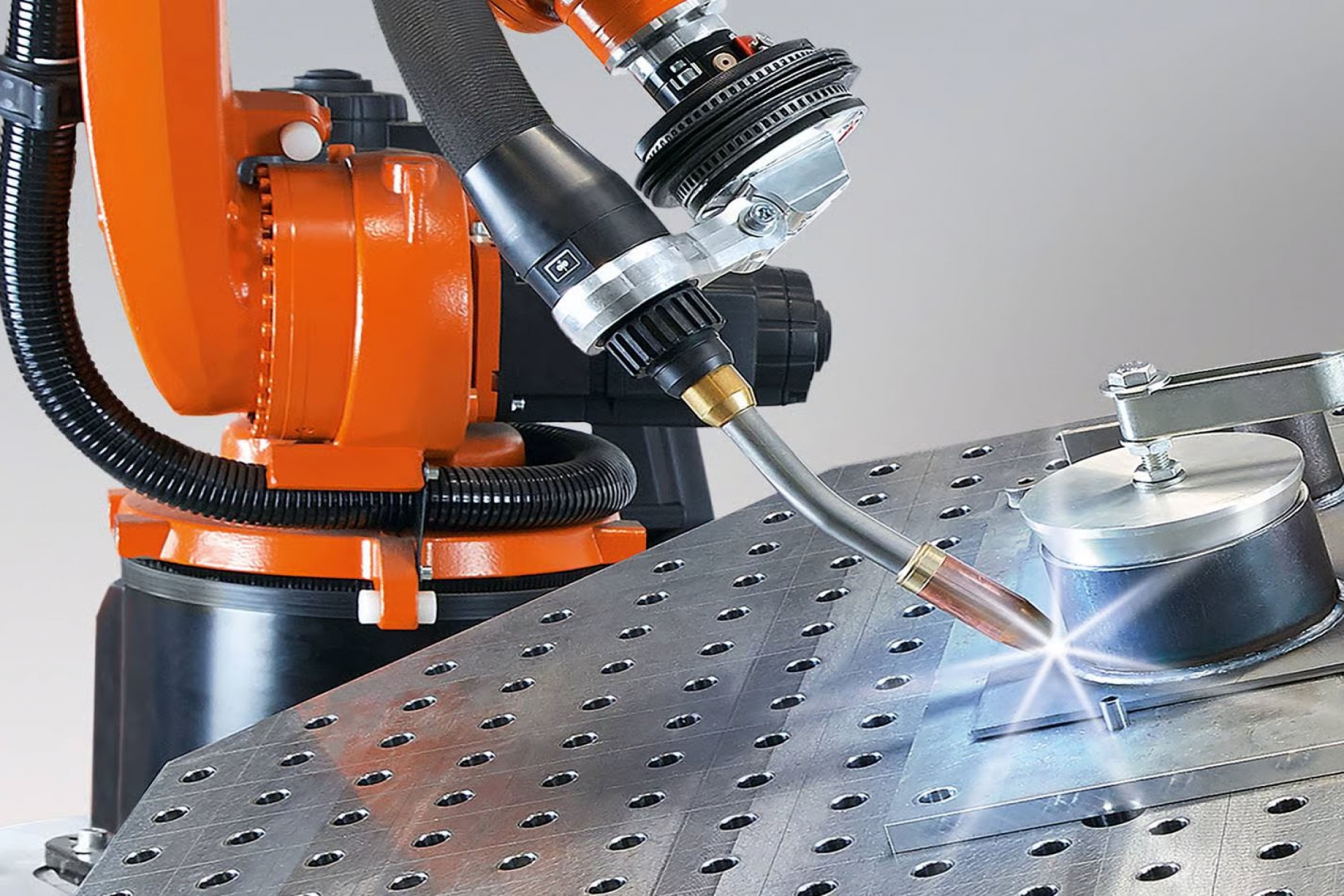

At Essiz Metal, we continuously strive to invest in the most modern production techniques. One of the most important innovations within our production capacity is robot welding. With this advanced technology, we combine speed, precision, and efficiency, enabling us to deliver the highest quality to our customers in both small-scale and large-scale projects.

What is robot welding?

Robot welding is a fully automated welding process in which industrial robots are used to join metal components. These robots are programmed to produce highly accurate weld seams, ensuring consistent quality and high production speed. Since robots can operate 24/7, this method is particularly suitable for mass production and repetitive welding tasks.

Advantages of robot welding at Essiz Metal

We use the latest generation of welding robots, specifically designed for a wide range of applications in the metal industry. The main advantages include:

Consistent quality: Robots always deliver the same accuracy, regardless of batch size.

High production speed: Efficient and ideal for large production volumes.

Cost savings: Fewer labor hours and reduced material waste.

Safety: Hazardous conditions are handled by robots, reducing risks for employees.

Precision: Extremely tight weld seams, ideal for parts where aesthetics and durability are crucial.

Applications of robot welding

Robot welding is used in a wide variety of sectors, including:

Automotive industry: Production of car bodies and parts requiring absolute precision.

Machine building: Manufacturing complex machine components with consistent quality.

Shipbuilding: Welding heavy structures and components capable of withstanding extreme conditions.

Construction: Large metal structures such as frames, beams, and pipelines.

Thanks to the versatility of robot welding, we can deliver both standard projects and customized solutions, fully tailored to the specific requirements of our customers.

Quality and reliability

At Essiz Metal, quality is central. Our robot welding processes are continuously monitored by experienced specialists who ensure that every project meets the strictest European standards. In addition, we regularly invest in new software and programming, ensuring our robots remain up to date with the latest technology.

Innovation and vision for the future

Automation is no longer the future—it is the present. With robot welding, we respond to the increasing demand for efficient and sustainable production methods. By investing in robotic technology, we strengthen our position as a leading company in metalworking and provide our customers with a competitive edge.

Why choose Essiz Metal?

Because we do more than just welding. We combine innovation, technology, and craftsmanship to provide solutions that meet the highest quality standards. With robot welding, we guarantee fast lead times, minimal error margins, and durable results.

At Essiz Metal, we believe that precision and automation are the key to the future of metalworking. With our robot welding solutions, we set a new standard in the industry.

Hic kayit yok!

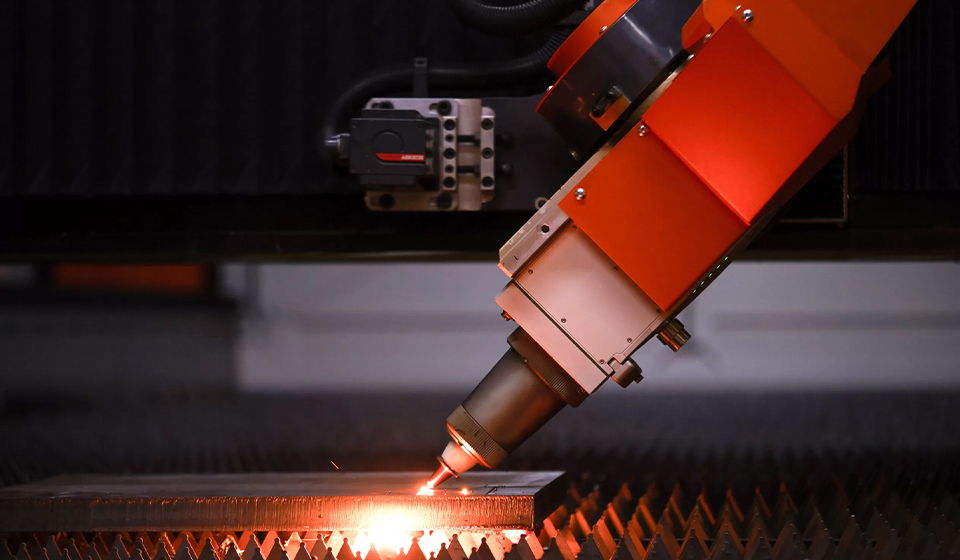

Essiz Metal was founded in 2008 and, in line with customer demands and technological developments, has grown into its current position. The main activity of our company is sheet metal cutting and bending. We operate cutting and bending machines with a capacity of 15 mm and a length of 6000 mm, as well as CNC laser cutting machines of 12000 x 3000 mm capable of processing sheets up to 50 mm.

COMPANY PROFILEYears of Experience

m2 Production Area

Tons Annual Production